Weifang Qianfeng Electromechanical Equipment Co., Ltd.

Discover how precast concrete pipe equipment revolutionizes construction efficiency while cutting costs. As a leading manufacturer of precast concrete component equipment, Weifang Qianfeng Electromechanical Co., Ltd. offers innovative solutions including concrete pipe equipment, lifting equipment, and concrete mixing plants. Our technology empowers information researchers, operators, and decision-makers to achieve faster project completion with superior quality. Learn why global contractors trust our one-stop precast solutions for time and money savings across Africa, South Asia, and beyond.

What is Precast Concrete Pipe Equipment and How Does It Work?

Precast concrete pipe equipment refers to specialized machinery designed for manufacturing standardized concrete pipes through controlled factory conditions. Unlike traditional cast-in-place methods, our precast systems utilize automated processes incorporating concrete mixing plants, steel cage welding machines, and high-precision pipe molding equipment. The production cycle begins with precise batching of raw materials in our computer-controlled concrete mixing plants, ensuring consistent quality. Reinforced steel cages are then fabricated using CNC welding machines before being placed into vibration-compacted molds. This industrial approach allows simultaneous curing of multiple units under optimal temperature and humidity, achieving 70% faster curing than on-site pouring. With lifting equipment integrated into production lines, finished pipes can be transported directly to storage yards or loaded for shipment within 24 hours of casting.

Comparative Advantages Over Traditional Construction Methods

Key Applications and Industry-Specific Benefits

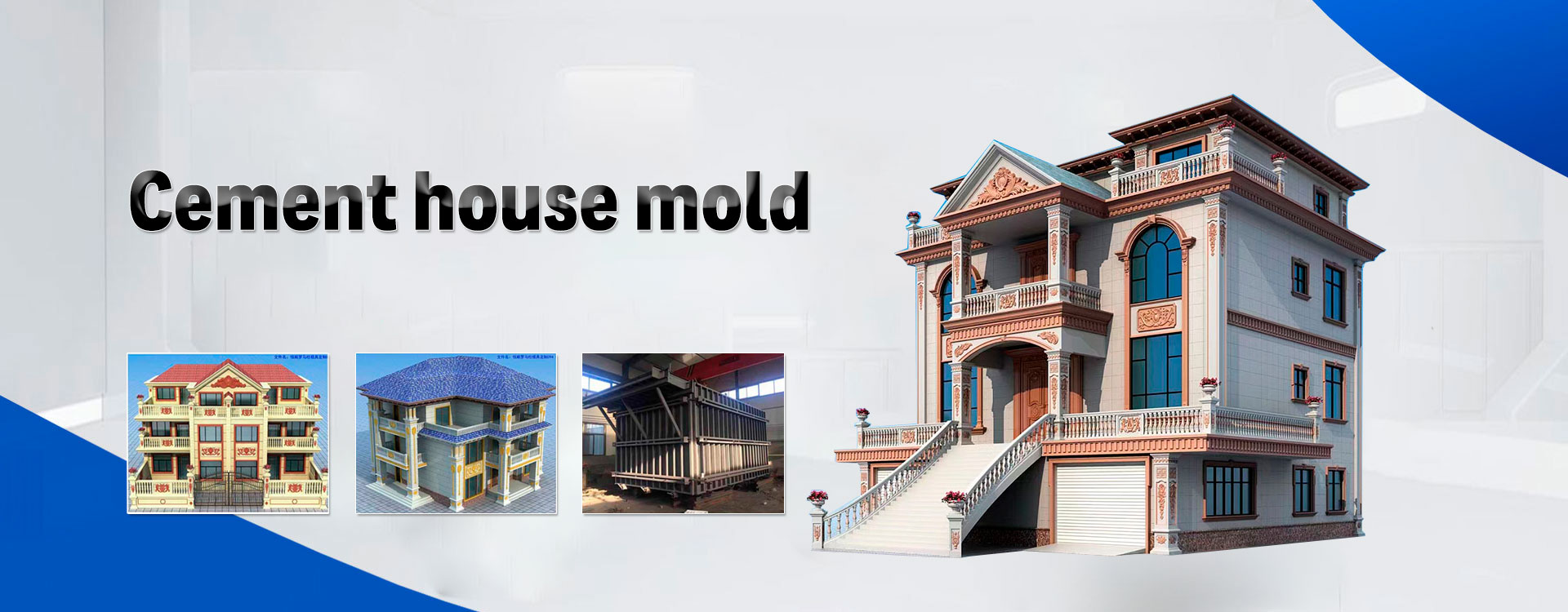

The versatility of precast concrete component equipment extends across multiple infrastructure sectors. In municipal drainage systems, our concrete pipe equipment produces ASTM C76-compliant pipes ranging from 12-inch to 144-inch diameters for stormwater management. For agricultural irrigation projects common in Africa and South Asia, we supply reinforced concrete u-groove equipment creating durable water channels resistant to soil erosion. The precast concrete house mold systems enable rapid construction of worker camps for mining operations, with complete structures installable within 72 hours of factory production. When integrated with our box culvert equipment, highway construction projects achieve accelerated bridge underpass completion while meeting AASHTO HB-17 load standards. Technical evaluators particularly value how our lifting equipment solutions facilitate safe handling of heavy precast elements, reducing installation risks by 90% compared to conventional crane operations.

Cost-Breakdown and Return on Investment Analysis

A detailed financial assessment reveals why enterprise decision-makers increasingly adopt precast solutions. Our concrete mixing plant configurations reduce cement consumption by 12-15% through optimized mix designs validated by EN 206 testing. For a typical 5km pipeline project, precast operations demonstrate: 35% savings in direct construction costs, 60% reduction in overtime expenditures due to predictable scheduling, and 80% lower quality remediation expenses. The modular nature of our concrete pipe equipment allows production line expansion without complete reinvestment, protecting capital expenditure. Contract administrators note that guaranteed dimensional accuracy (within ±2mm tolerance) virtually eliminates costly field adjustments during installation phases. When calculating total ownership costs over a decade, precast technology delivers 3.2x better ROI than conventional methods according to Dodge Data & Analytics benchmarks.

Addressing Common Misconceptions

Many first-time buyers express concerns about transport limitations of precast concrete components. However, our company's strategic location near multiple international airports and seaports enables cost-effective global logistics. Another frequent query involves perceived design inflexibility – in reality, our parametric CAD systems can produce custom pipe configurations including elliptical, arch, and baffled designs within 7 working days. Some operators initially question the need for specialized lifting equipment until experiencing our vacuum-assisted handling systems that prevent edge damage during installation. We clarify that precast doesn't eliminate but rather reallocates labor – shifting from hazardous site work to safer factory positions with better quality control.

Why Choose Weifang Qianfeng Electromechanical Co., Ltd.?

With 13 years of specialized experience in precast concrete component equipment manufacturing, we stand apart through: proprietary vibration-compaction technology achieving 98% densification (verified by ASTM C497), the industry's most comprehensive after-sales network covering 37 countries, and turnkey factory commissioning within 90 days from contract signing. Our concrete mixing plants incorporate German-designed twin-shaft mixers ensuring homogeneous batches for every pipe production cycle. Decision-makers appreciate our transparent costing model including detailed documentation of energy consumption metrics (averaging 11.3kWh/ton of production). Contact our engineering team today for a customized cost-benefit analysis tailored to your upcoming project requirements, or request virtual demonstration of our precast concrete pipe equipment in operation.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.