Weifang Qianfeng Electromechanical Equipment Co., Ltd.

Concrete Mixing Plant: Key to Quality and Efficiency

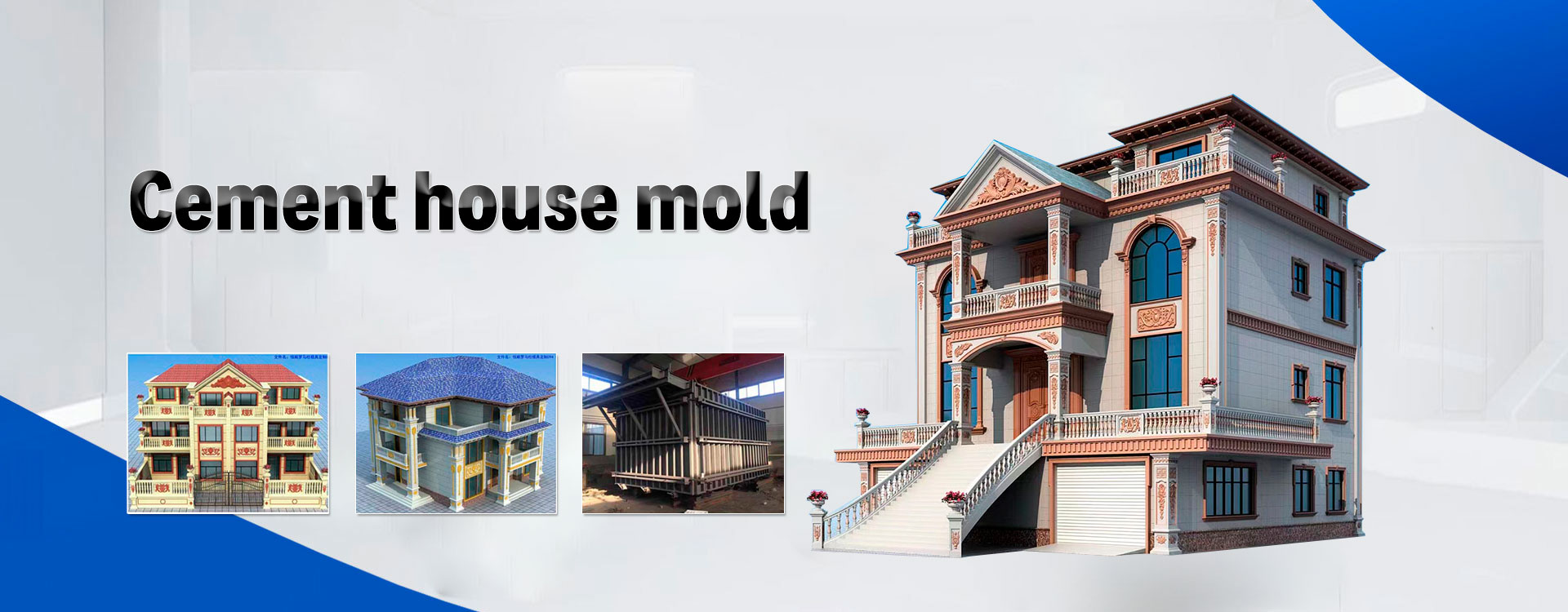

Discover how a high-performance Concrete Mixing Plant can revolutionize your precast concrete production. As a cornerstone of modern construction, our advanced mixing systems ensure precise batching for Precast Concrete Component Equipment, Concrete Pipe Equipment, and specialized Concrete House Mold applications. Whether you're a project manager evaluating efficiency or an operator seeking reliable Lifting Equipment integration, this guide explores the technical advantages that drive quality and productivity in today's competitive construction landscape.

1. Defining the Modern Concrete Mixing Plant

A Concrete Mixing Plant is the industrial heart of any precast operation, combining raw materials like cement, aggregates, water, and admixtures with scientific precision. Unlike traditional manual mixing, our automated plants adhere to ISO 9001 and EN 206 standards, achieving consistency variances below 2% – critical for manufacturing high-tolerance Precast Concrete Component Equipment. The system comprises four core modules: aggregate batching (with ±1% accuracy), cement silos (preventing moisture contamination), computer-controlled mixing cycles (optimizing hydration), and integrated Lifting Equipment for mold handling. For projects requiring mass production of Concrete Pipe Equipment, our twin-shaft mixers deliver 180-second cycles while maintaining 98% homogeneity – a benchmark verified by third-party ASTM C94 testing.

2. Technical Superiority in Precast Applications

3. Operational Economics for Decision Makers

For enterprise buyers comparing CAPEX investments, our Concrete Mixing Plants demonstrate ROI within 18-24 months through three levers: Energy efficiency (25kWh/ton vs industry average 35kWh), reduced labor (one operator manages 120m³/hr output), and near-zero material waste (98.6% batching accuracy). When paired with automated Lifting Equipment, a single plant can service 15+ Concrete House Mold stations simultaneously – ideal for Southeast Asian markets where labor costs are rising 12% annually. Our clients in Nigeria achieved 340% production growth after replacing manual mixing with our 90m³/hr model, leveraging IECEx-certified explosion-proof motors for hazardous environments.

4. Future-Proofing Through Smart Integration

The next evolution connects Concrete Mixing Plants with Industry 4.0 ecosystems. Our IoT-enabled models feature: Predictive maintenance (vibration analysis on mixer bearings), real-time slump adjustment via weather APIs, and blockchain-based material tracing for LEED certification. A recent Dubai precast factory using these systems reduced energy use by 19% while achieving EN 13369 Class 3 durability for offshore Concrete Pipe Equipment. As BIM adoption grows, our plants now import mix designs directly from Revit files – eliminating manual entry errors for technical evaluators.

Why Choose Weifang Qianfeng?

- Global Compliance: CE, GOST-R, and AS/NZS 4994.1 certifications

- Turnkey Support: From factory layout planning to operator training

- Localized Service: 48hr response time through regional warehouses in Kenya, Vietnam, and Peru

- Material Science Partnership: Joint R&D with BASF on high-performance admixtures

Ready to transform your precast production? Our engineers are available 24/7 for customized plant design consultations. Request your capacity analysis report today.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.