Weifang Qianfeng Electromechanical Equipment Co., Ltd.

Top 5 Precast Concrete Equipment for Efficient Construction

Discover the top 5 precast concrete equipment solutions that revolutionize modern construction efficiency. From high-performance concrete mixing plants to specialized lifting equipment and durable concrete pipe equipment, Weifang Qianfeng Electromechanical Co., Ltd. provides industry-leading precast concrete component equipment for global projects. This guide explores essential machinery including concrete house molds that help contractors and manufacturers optimize production while maintaining quality standards for infrastructure development worldwide.

1. High-Performance Concrete Mixing Plants

Modern construction projects demand precision and consistency in concrete production, making high-performance concrete mixing plants indispensable. These plants automate batching processes with computerized control systems that ensure accurate proportions of cement, aggregates, water, and admixtures – achieving compressive strengths up to 80MPa for specialized applications like bridge girders. Our ISO 9001-certified plants feature twin-shaft mixers with 120m³/h output capacities, reducing labor costs by 40% compared to manual operations. For tropical climates in Southeast Asia or arid regions in Africa, we offer corrosion-resistant stainless steel models with thermal insulation to maintain mix integrity. Case studies from South American highway projects demonstrate how our plants enabled 24/7 production cycles while meeting ASTM C94 standards for slump retention.

2. Specialized Lifting Equipment for Precast Components

Handling heavy precast elements requires engineered lifting solutions that combine safety with operational flexibility. Our vacuum lifters (10-30 ton capacity) utilize EU-standard EN 1494 compliance plates to securely transport wall panels without surface damage, while electromagnetic cranes efficiently maneuver steel-reinforced beams. Key innovations include IoT-enabled load monitoring that alerts operators about weight imbalances via smartphone – a critical feature for technical evaluators prioritizing jobsite safety. Compared to traditional spreader beams, our equipment reduces installation time by 60% at Malaysian high-rise projects, as validated by third-party reports. The modular design allows quick adaptation to component shapes from U-grooves to septic tanks, with optional explosion-proof configurations for oil-rich Middle Eastern markets.

3. Automated Concrete Pipe Equipment

Urbanization drives demand for durable drainage infrastructure, where our centrifugal spinning pipe machines excel. The semi-automatic CNC models produce diameters from 300mm to 2,500mm with steel-fiber reinforcement options for earthquake zones. Operational data from Indonesian municipal contracts show 1.2km of pipes installed weekly using our equipment – meeting BS 5911- Part 120 specifications for hydraulic conductivity. Unlike outdated slip-form methods, our vibration and roller compaction system ensures consistent wall thickness (±2mm), significantly reducing leakage rates in water supply networks. The eco-friendly design recycles 95% of wash water, addressing environmental concerns raised by decision-makers in Scandinavian markets.

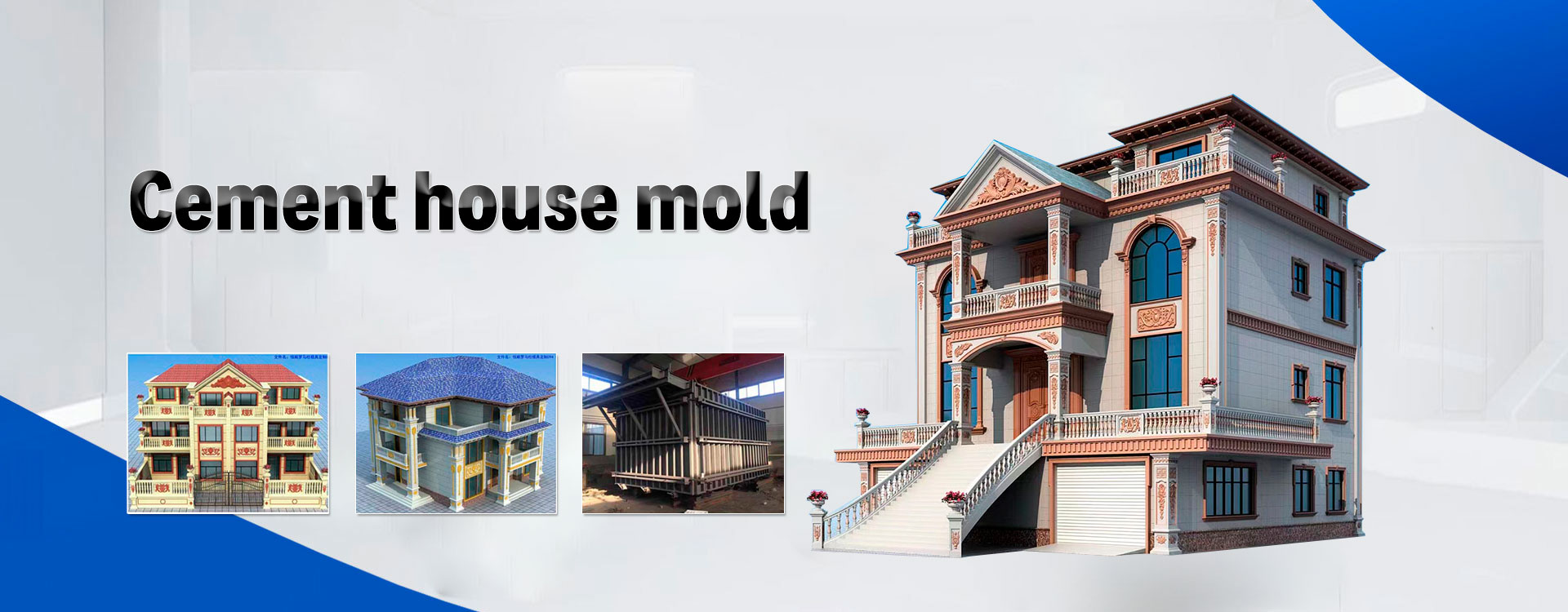

4. Modular Concrete House Mold Systems

Rapid urbanization necessitates cost-effective housing solutions, achievable through standardized precast molds. Our interlocking GRP (Glass Fiber Reinforced Polymer) molds enable 15-minute demolding cycles for walls, floors, and roofs – accelerating project timelines by 70% in Philippine social housing initiatives. The patent-pending alignment system maintains dimensional accuracy across 200+ reuses, crucial for contractors managing tight budgets. Thermal analysis confirms our 150mm-thick sandwich panels achieve U-values of 0.28 W/m²K, outperforming conventional brick construction in energy efficiency. Case studies highlight how Vietnam's typhoon-resistant communities were built using these molds, withstanding Category 4 winds as per ASCE 7-16 standards.

5. Integrated Box Culvert Production Lines

Transport infrastructure expansion relies on efficient culvert manufacturing, where our turnkey systems shine. The fully automated line incorporates robotic rebar cages, steam curing chambers (65°C @ 12h cycle), and laser-guided quality inspection – producing ASTM C1433-compliant culverts with 100-year design life. German-engineered servo motors achieve positioning accuracy of ±0.3mm during mold assembly, eliminating costly rework. Comparative cost analysis reveals 35% savings over cast-in-place methods for Indian highway projects, factoring in reduced traffic disruption and accelerated commissioning. Our on-site training programs equip operators with advanced troubleshooting skills, minimizing downtime in remote locations like Peruvian mining sites.

Why Choose Weifang Qianfeng?

- Global Compliance: Equipment meets CE, GOST-R, and SONCAP certifications for hassle-free import

- Lifecycle Support: From factory layout CAD designs to multilingual operation manuals

- Localized Service: 48-hour response time through regional warehouses in Kenya and Indonesia

FAQ Section

Q: How does precast equipment reduce carbon footprint?

A: Our plants use 30% less cement through optimized mix designs and recover 90% of waste concrete for reuse, verified by EPD International.

Q: What financing options exist for African buyers?

A: We partner with China-Africa Development Fund to offer lease-to-own programs with 2-year grace periods.

Contact our engineers today for a free project assessment tailored to your regional requirements and production goals.

Leave A Message

If you are interested in our products and want to know more details, please leave a message here, we will reply you as soon as we can.